The 2015 Definition of Solid Waste (DSW) rule provided, in part, that hazardous secondary material generated and then transferred to a Verified Reclamation Facility (VRF) for the purpose of reclamation is not a solid waste provided that certain criteria are satisfied – this includes spent catalysts and tank bottoms. See HW118 in the Louisiana Register.

Following a vacatur of the federal regulation by the D.C. Circuit Court of Appeal in July 2017, EPA amended its hazardous waste regulations to reinstate the transfer-based exclusion (TBE) and remove the VRE. However, EPA has allowed states to maintain the VRE because it is more stringent than the federal rule.

In a final rule published in May 2018, EPA established four categories for state authorizations after the D.C. Circuit vacatur. Louisiana qualified as a state that had adopted the federal VRE but was not yet authorized to implement it. EPA granted final authorization of the State Hazardous Waste Management Program Revision to Louisiana on December 26, 2018. See, 83 Fed. Reg. 66,143.

In the final rule, EPA reiterated that “standards and criteria for variances from the classification of solid waste … are more stringent than the existing federal hazardous waste program, (see here for hazardous waste cleaning) including the transfer-based exclusion.” Thus, LDEQ’s program is considered “broader in scope” than the federal regulations. Although EPA cannot enforce requirements that are broader in scope, compliance is still required by Louisiana law.

Where is the 2018 Definition of Solid Waste Rule in Effect?

The 2018 Definition of Solid Waste (DSW) rule came into effect immediately in states, territories, and tribes that are not authorized by the Resource Conservation and Recovery Act (RCRA), which includes Iowa and Alaska.

All states are highly encouraged to adopt the 2018 DSW final rule, and some sections of the rule, like the definition of legitimate recycling at title 40 of the Code of Federal Regulations (CFR) in section 260.43, are mandatory and will eventually be adopted by every state.

However, the three solid waste exclusions—the generator-controlled exclusion (40 CFR section 261.4 (a) (23)), the revised transfer-based exemption (40 CFR section 261.4(a) (24) and (25)), and the remanufacturing exemption (40 CFR section 261.4 (a) (27)) —that were added to 40 CFR part 261.4 (a), are all optional because they are less stringent than the 2008 DSW, and therefore each state has the option of whether to adopt them.

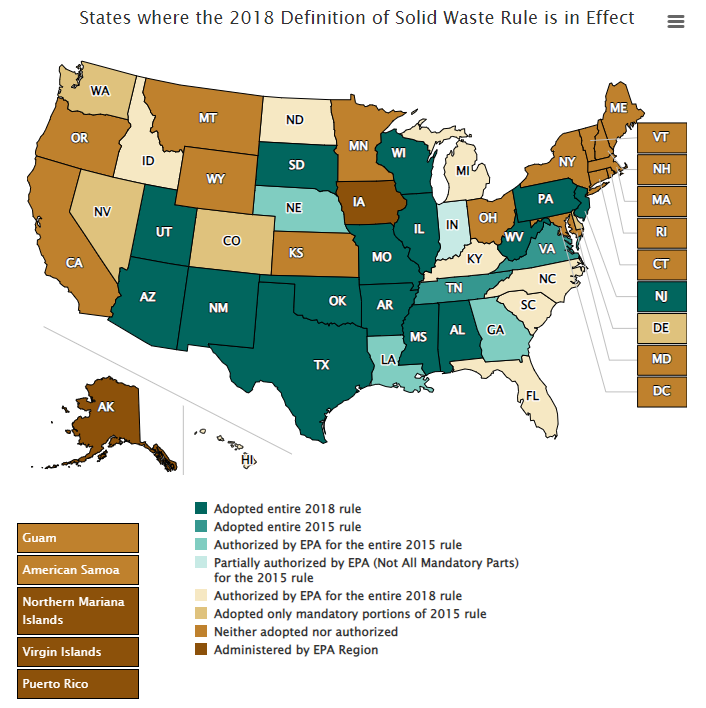

Additionally, as you can see from the map below, a few states have adopted a 2015 version of the DSW rule that includes the exclusion currently found in 40 CFR sections 261.4(a) (24) and (25). Because these 2015 DSW exclusions are more stringent than their 2018 counterparts, these states do not need to revise their programs, although EPA encourages them to do so.

Interstate Transport Between States with Different Versions of 40 CFR Section 261.4(a)(24)

Per EPA:

Generators operating under the 2018 DSW Rule that need to send their material to a reclamation facility regulated by the 2015 DSW rule, have two options: they can either transport it to a RCRA-permitted center or an unlicensed one with a validated recycler variance in accordance with the destination state’s regulations. In this case, though, generators must also carry out “reasonable efforts” audits at such sites per requirements from their home states.

Furthermore, if hazardous secondary materials are transported through a state that has not adopted the exclusion, this can lead to being subject to the transit state’s hazardous waste regulations once it crosses their border. Thus, we strongly suggest companies reach out to all states they anticipate transporting these substances across in order ensure regulatory compliance with each of them.

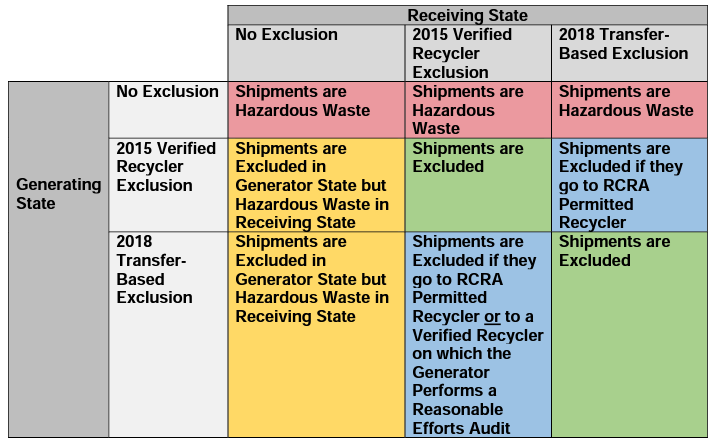

Status of Hazardous Secondary Materials Shipments Depending on Which Version of 40 CFR Section 261.4(a)(24) Has Been Adopted

Verified Recycling Exclusion (VRE)

The Amlon Group’s Port Allen facility currently operate pursuant to a VRF Variance issued by the LDEQ. Oil-bearing hazardous secondary material (OBHS) transported to The Amlon Group’s facility for reclamation that meets specified criteria is thereby excluded from the definition of a solid waste (and by extension a hazardous waste) – this includes spent catalysts, tank bottoms, and other materials designated by the OBHSM variance. The variance allows facilities to send material on a bill of lading (BOL) as hazardous secondary material.

The following map (also on EPA’s website) depicts the states where generators are authorized to send excluded material to verified reclamation facilities within the U.S. Facilities located in states shown in green or yellow are currently authorized to send material to Amlon Group’s facilities if all VRE criteria and conditions of the variance are satisfied.

See – Table with State Adoption and Authorization Status for the Definition of Solid Waste Rules

Defining what sustainability means for oil reclamation

The Amlon Port Allen and Longview Facilities provide Sustainable Solutions for hydrocarbon management through Innovative Recovery Techniques utilizing proven thermal and mechanical processes.

Both Port Allen and our Longview Facility offer refineries access to thermal desorption and separation technologies. Focused on treating refinery related materials, our services are designed to help your plant increase sustainability by diverting your oil bearing materials from landfills or incineration to our plants, where they can be treated in our reclamation processes.

About The Amlon Group

Servicing customers across the country, The Amlon Group is uniquely positioned to help you with sustainable, responsible, and efficient end-to-end solutions.

The Amlon Group will manage your materials through responsible and environmental treatment, storage, and disposal facilities. We will help you create the most suitable, environmental, and efficient plan for your company’s specific needs.

Safety and compliance

Keeping safety and compliance as the top priority

The Amlon Group’s operations have been audited and inspected, and take pride in a rigorous protocol that is in compliance with local, state, and federal standards. The Amlon Group has a comprehensive emergency management plan and are committed to keeping safety as our number one priority.

References

1. EPA’s 2018 Definition of Solid Waste Rule and its Effect in Louisiana

2. Where is the 2018 Definition of Solid Waste Rule in Effect?

Learn more about our catalyst recycling services

Conserve resources, save costs, and reduce waste and landfill burden with The Amlon Group’s catalyst recycling services.